Flexible “twins” provide economical hot strip production in a wide product range

SMS group supplied a twin-stand Steckel mill to the Chinese customer Shandong Tisco Xinhai Stainless Co., Ltd., being installed at the Junan location in the Chinese province of Shandong. The twin-stand Steckel mill ensures the economical production of hot strip in a wide range of products with very good quality but in relatively small quantities or smaller lot sizes.

In China, Shandong Tisco Xinhai Stainless Co., Ltd. is one of the largest manufacturers of nickel alloys.

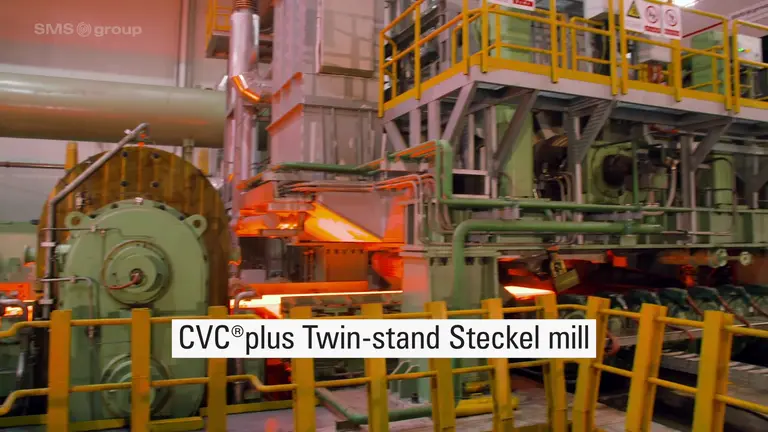

SMS group supplied all essential units belonging to the twin-stand Steckel mill. These include a primary descaler, a four-high reversing roughing mill with attached edger and a drum shear upstream of the Steckel stands. The centerpieces of the hot rolling line are the two four-high stands with one Steckel furnace each in the entry and exit section. The Steckel stands have proven CVC® plus technology (Continuously Variable Crown) for roll shifting. In conjunction with the negative work roll bending, the profile and flatness are precisely adjusted and product tolerances are achieved which correspond to those in modern hot strip mills.

SMS group supplied the entire mechanical equipment with comprehensive support by the regional set-up in China. The scope of supply also included the complete X-Pact® electrical and automation system for the entire production line.

Laminar cooling section and a stationary downcoiler completet the scope of mechanical delivery. The foundations are already being prepared accordingly so that Xinhai Industry can retrofit a second downcoiler later if necessary.

With this plant configuration, Xinhai Industry mainly rolls hot strip made of stainless steels, duplex steels and heat-resistant steels.

With this plant configuration, Shandong Tisco Xinhai Stainless Co. Ltd., is able to roll hot strips up to 2mm final thickness made of stainless steels including duplex steels and heat-resistant steels. The maximum annual capacity sums up to impressing 1.75 million tons of these special steel grades.

Impressions

Main data

- Material: stainless steel, duplex steel, heat resistant steel

- Slab thickness (max.): 230 mm

- Slab width (max.): 2,100 mm

- Slab length (max.): 12,000 mm

- Transfer bar thickness: 25 – 40 mm

- Tansfer bar width (max.): 2,100 mm

- Strip thickness: 2 – 16 mm

- Strip width: 1,000 – 2,100 mm

- Capacity: 1.75 million t/year