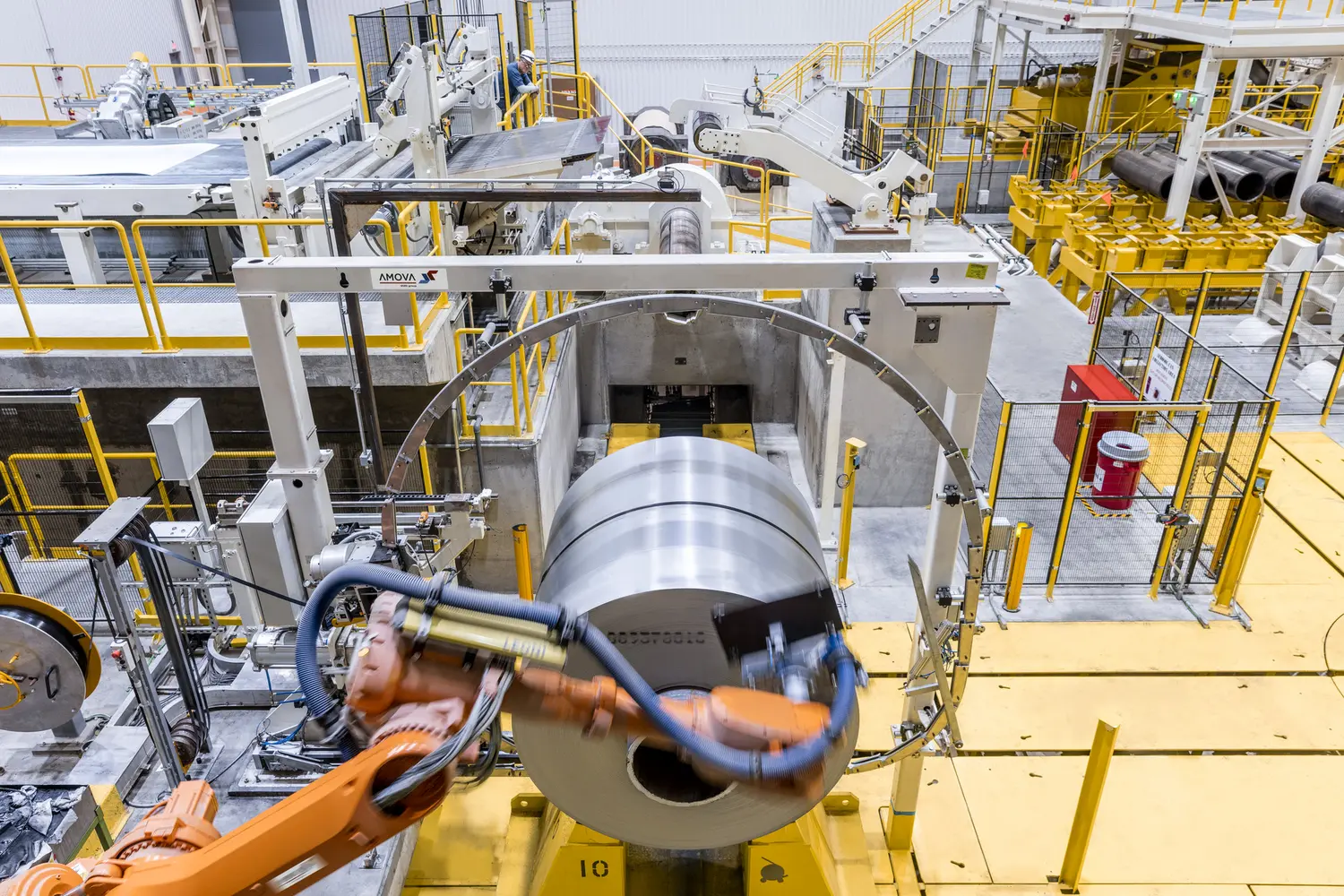

We integrate robotics into flat rolling plants to enhance operational efficiency and safety. Our robotic systems are seamlessly integrated into the main automation and can be remotely operated via the X-Pact® Vision HMI.

Processes such as destrapping at coil prep stations or zinc dross removal in galvanizing lines are now automated, ensuring safety and efficiency.

Additional benefits include increased productivity, high system availability, and reduced operating costs. The comprehensive portfolio of applications also covers tasks like coil labeling and marking.

-

Automatic coil destrapping

Automatic strap removal with flat coils debander

With seamless strap winding and disposal capabilities, the flat coils debander ensures that material handling is both swift and effective. The system features fully automatic movements, reducing manual intervention and minimizing downtime. Its integration with plant automation systems allows for streamlined operations and improved productivity, aligning perfectly with modern industrial standards. The application is equipped with enhanced safety features to protect both workers and equipment.

![]()

-

Eye strapping/Strapping

Strapping depending on requirements

Strapping machines are tailored to meet specific needs, allowing for single or multiple strappings of large and slit coils through the eye or around the circumference. Options include longitudinal or transverse strapping machines for metal sheets and sheet packs, with the possibility of incorporating wooden spacers.

-

Dross removal for galvanizing lines

Efficient Zn dross removal

The system features an anthropomorphic robot equipped with a specialized tool, heat and dust protection, and an internal cooling system. It is precisely parametrized to meet customer requirements and accommodate potential layout constraints. An optional automatic ingot feeder complements the system as a single package unit, facilitating the storage and refilling of up to five ingots via forklift. This ensures the galvanizing process remains continuous and efficient, maintaining a steady bath level to optimize production consistency.

Seamless integration with existing plant automation systems further enhances operational synergy, making this application a smart addition to any galvanizing line.

-

Automatic spray marking

Flat coils marking system

This application offers automatic spray marking, utilizing either single or multi-nozzle heads to deliver precise and efficient results. With integrated paint and ink management, the system ensures optimal resource utilization and minimal waste. It is capable of marking bar codes, QR codes, sentences, and numbers, providing versatile options to meet diverse operational needs.

The application features fully automated movements, reducing manual handling and enhancing throughput. Seamless integration with plant automation ensures consistency and reliability across the production line.

![]()

-

Labeling of flat coils

Streamlined labelling process

This advanced application offers automatic printing and application of sticky labels, accommodating sizes up to ISO A4. It is engineered to work efficiently on both clean and slightly oiled surfaces, ensuring versatility in various operational conditions.

Equipped with automatic coil measurement, the system guarantees precise label placement, enhancing accuracy and consistency. A backup label printer is available to ensure uninterrupted operations, minimizing potential downtime. The application supports the labelling of bar codes, QR codes, sentences, and numbers, providing comprehensive marking solutions.

With automatic movements, the robotics application reduces manual intervention, boosting productivity. It seamlessly integrates with plant automation systems, facilitating smooth and efficient workflow management.

-

Logistics

Transport, storage and packaging logistics for coils

In terms of logistics, SMS group offers comprehensive solutions, including automated high-bay storage systems and automatic coil transportation systems, designed to optimize throughput times while safeguarding materials from damage. Packaging systems - available as manual, semi-automatic, or fully automatic - are tailored to specific requirements to ensure product protection during shipping.

![]()