Robotics applications for meltshops

The integration of robotics in meltshops offers numerous advantages in enhancing operational safety and efficiency. These robotics applications are fully integrated into the main automation and can be remotely controlled via the operator's X-Pact® Vision HMI.

For example, X-Pact® Sampler automatically performs required measurements on liquid steel – safely, efficiently, and without the need to have a man on the floor. Further advantages of robotics include improved productivity, high availability, and lower operating costs. It is available in various options to enable a best possbile modernization upgrade of existing equipment.

-

X-Pact® Sampler

X-Pact® Sampler is a robotic application designed to substitute the dangerous manual operation of taking measurements and collecting samples from a molten steel bath like in BOF, EAF, LF and VTD.

The solution is able to perform from simple functionality to fully automatic cycles that include cartridges pick-up from magazine, sample cutting and delivery, scraping of used cartridges, lance deformation compensation and lance substitution management.Trusted technology by ABB and COMAU

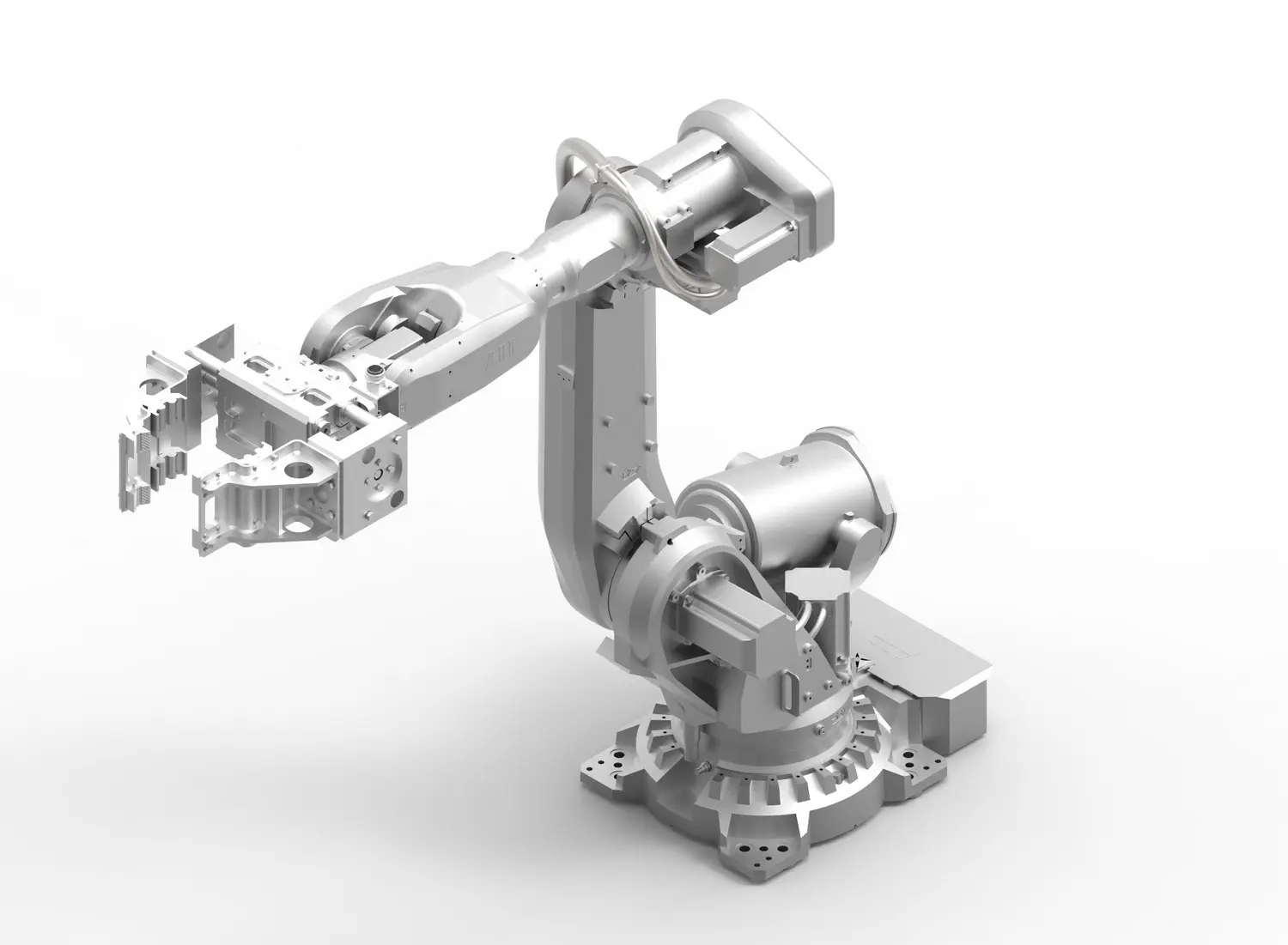

X-Pact® Sampler is a robotic application for sampling and measurements on liquid steel that is using anthropomorphic robots supplied by global vendors like ABB and COMAU. The design includes lances for different types of cartridges as well measurement instruments. The product is completely integrated into the main automation and can therefore be controlled remotely from an operator HMI. A local panel is available for maintenance. Safety fences and safe volumes zones protect the robot cell.

Key features

- Adaptable to any layout and multitool

- Provides sampling-, temperature-, oxygen, hydrogen measurement, as well as refractory camera scan

- Enables automatic sample cut and delivery

- Technical assistance after sales

-

X-Pact® Sampler at BOF sublance

- Automatic cartridge installation, removal and disposal

- Automatic cartridge storage, adjustable autonomy

- Automatic movements

- Integration with plant automation

- Enhanced safety

![]()

Let's get in touch!

Use our contact form for questions, inquiries or personal contact.