Keep your plant at the cutting edge of technology

In the fast-paced world of industrial production, staying ahead requires continuous modernization and upgrades. Our offerings include value-added components that enhance your plant's capabilities and standardized upgrades that ensure seamless integration with existing systems. Electric and automation upgrades are designed to optimize efficiency and reliability, while digital upgrades leverage the latest technological advancements to transform your operations.

Our full-line modernization services provide a comprehensive overhaul of your plant, ensuring every aspect is optimized for peak performance. We also offer targeted component and equipment upgrades, addressing specific areas for improvement and ensuring that your facility operates at its highest potential.

By embracing our modernization and upgrading solutions, you can achieve a significant increase in production, enabling you to meet growing demand and expand your market presence. Our services facilitate the extension of your product mix, allowing you to diversify offerings and capture new opportunities. Additionally, the reduction of operational costs is a key benefit, resulting in improved profitability and long-term sustainability.

With our expertise and innovative solutions, you can ensure that your plant remains at the forefront of technology, driving success and growth in a competitive landscape.

-

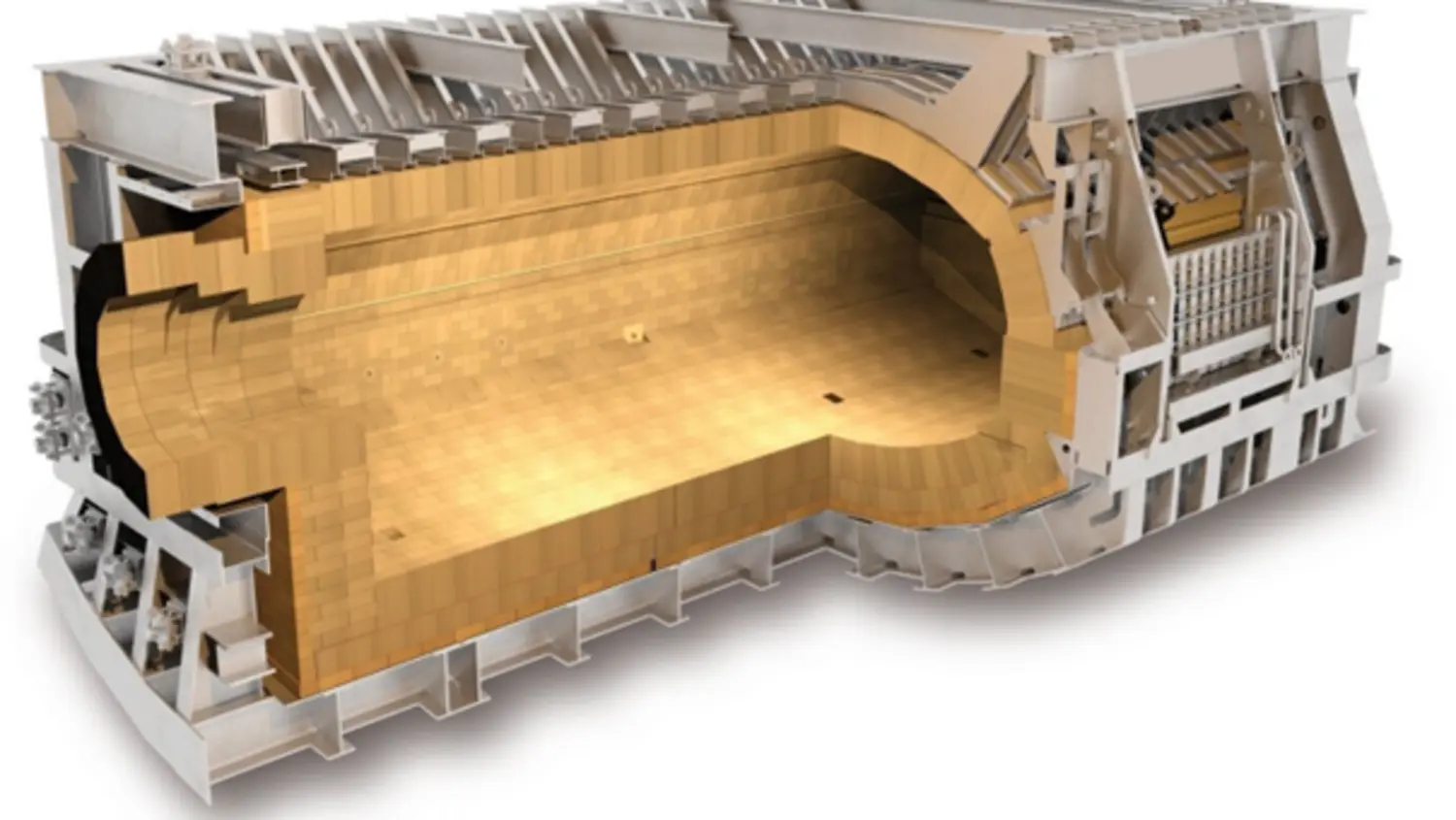

Production increase for tilting refining furnace

For those seeking to quickly increase overall production capacity, the Capacity upgrade for tilting refining furnaces (TRF) offers a streamlined solution. SMS group is committed to supporting you throughout the entire process, from conducting a feasibility study to determine the possibilities for your specific production line, to reconstructing with customized spare parts, and finally commissioning the upgraded plant. Our upgrade process begins with a thorough clarification of plant-specific upgradeability, taking into account production fit and steelwork integrity. This ensures that any enhancements are perfectly aligned with your existing infrastructure.

By increasing productivity without the need for new plants or additional space in your production facility, you can achieve significant improvements without the complexities associated with expanding physical operations. Throughout the modernization process, we maintain high process safety, ensuring seamless transitions from the initial study to commissioning. SMS group provides all required engineering and spare parts from a single source, offering a cohesive and integrated approach to your capacity upgrade needs. With the TRF Capacity Upgrade, you can confidently elevate your production capabilities, optimizing efficiency and maximizing output within your current facilities.

![]()

-

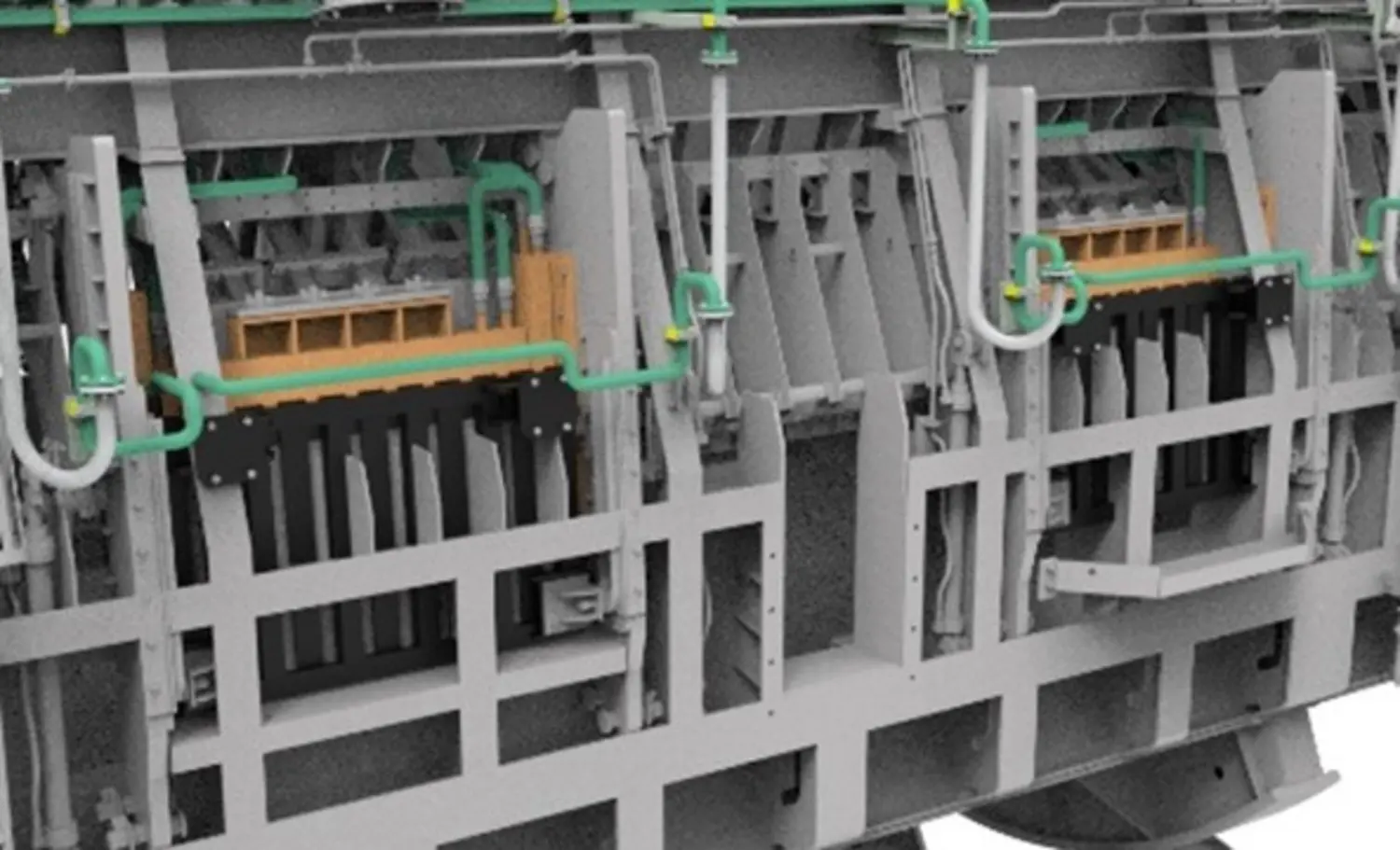

Cooled copper frame upgrade for tilting refining furnace

Transitioning to cooled copper frames from traditional steel frames is a strategic upgrade that enhances plant durability and efficiency. Cooled copper frames enables the slag to freeze onto the frame body, shielding the area from the overall furnace atmosphere. This prevents the risk of door leakage through worn out door frames, ensuring high process safety. Additionally, the copper frames enable equal force distribution in the refractory bricks, which leads to a significant increase in refractory lifetime.

Overall, this modernization increases process safety, extends refractory lifetime, and boosts productivity by minimizing downtimes, while also improving end-wall stability for greater structural integrity and operational reliability.

![]()

-

Enhanced stability and safety by vessel optimization for Peirce-smith converters

SMS group's PSC Vessel & Binding System Integrity Optimization offers superior stability and safety by transitioning to single-shaped vessels. Single-shaped vessels resist deformation more effectively than those with screwed-on endwalls. This strategic upgrade enhances geometrical stability, protects against outbreaks, and facilitates even brick force distribution, thereby extending refractory lifetime and simplifying maintenance.

SMS group offers solutions based on your plant’s specific needs by assessing the optimized replacement strategy, depending on current state of the plant (vessel deformation, plant layout, etc.). This includes the definition of parts to be replaced (Endwalls, vessel elements, etc.), as well as the definition of the detailed replacement sequence. SMS group provides all required engineering and spare parts from a single source, offering a cohesive and integrated approach, minimizing downtimes during replacement and providing a perfectly fitting and safe new setup.

Achieve greater reliability and performance in your production processes with optimized vessel integrity.

![]()

-

Keep your plant at the cutting edge of technology

SMS group's virtual erection engineering, first applied in the Aurubis project for Peirce-Smith converter replacement, utilizes 3D models and 4D engineering to enhance erection planning. By integrating detailed time scheduling with 3D engineering on a unified platform, SMS ensures efficient communication among teams and reduces errors in project planning. This approach optimizes design by considering manufacturing, transport, and erection needs, offering services like technical consulting, 3D laser scanning, VR and AR modeling, and comprehensive erection planning. The goal is to achieve a perfectly scheduled and engineered equipment installation, delivered transparently, on time, and within budget.

![]()