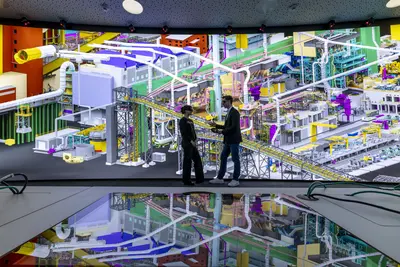

Behind an inconspicuous door on the ground floor of the SMS Campus in Mönchengladbach, visitors are greeted by a fascinating high-tech world. A huge LED screen dominates the room, and in front of it are two rows of workstations and monitors recessed in the tables. “Right now, this is the largest curved LED screen with multi-user tracking worldwide,” explains Eugen Bolotin, a member of the SMS TECademy team. “It is 12.2 m wide and almost 3.5 m high and consists of 800 LED tiles. Thanks to its enormous size and high resolution (2x4k), the screen offers us entirely new possibilities when it comes to creating training content. Combined with the use of shutter glasses, the screen also enables stereoscopic (spatial) vision. Thanks to a refresh rate of 240 Hz, we can even display separate images for two groups at the same time.”

The digital classroom is part of the SMS TECademy, where experts are on hand to train our customers’ employees. Typical examples include hydraulic system training. “By covering everyday maintenance situations in such precise detail, the training is extremely effective. For example, virtual tours through the pump station are an integral part of the training.” Alongside the LED screen-based training, our digital classroom also offers VR training with interactive self-learning modules.

Yet the room is not only used for training. Eugen Bolotin: “The giant screen is perfect for showing our plants in their entirety as well in incredibly fine detail. This means you can gain an overall impression of the whole facility while simultaneously studying its technical details.” The renderings are based on the 3D design data for specific customer projects. This makes the room ideal for internal design reviews or meetings with customers. Complex topics can be discussed specifically on the 3D model and clarified early on. The tool is particularly valuable for elaborate modernization projects. The 3D model of the plant can be embedded in a specific environment, if, for example, a suitable laser scan has been created in advance. “This enables us to better integrate new equipment into the existing infrastructure and avoid time-consuming and expensive modifications during the revamp phases,” adds Eugen Bolotin.