As a producer of aluminum extrusions, you benefit from our bundled know-how: Hand in hand with our strong partners OMAV and IAS, we offer the full range of products and services for extrusion plants: From energy-efficient heating systems through modern extrusion presses to highly developed auxiliary and outlet devices.

-

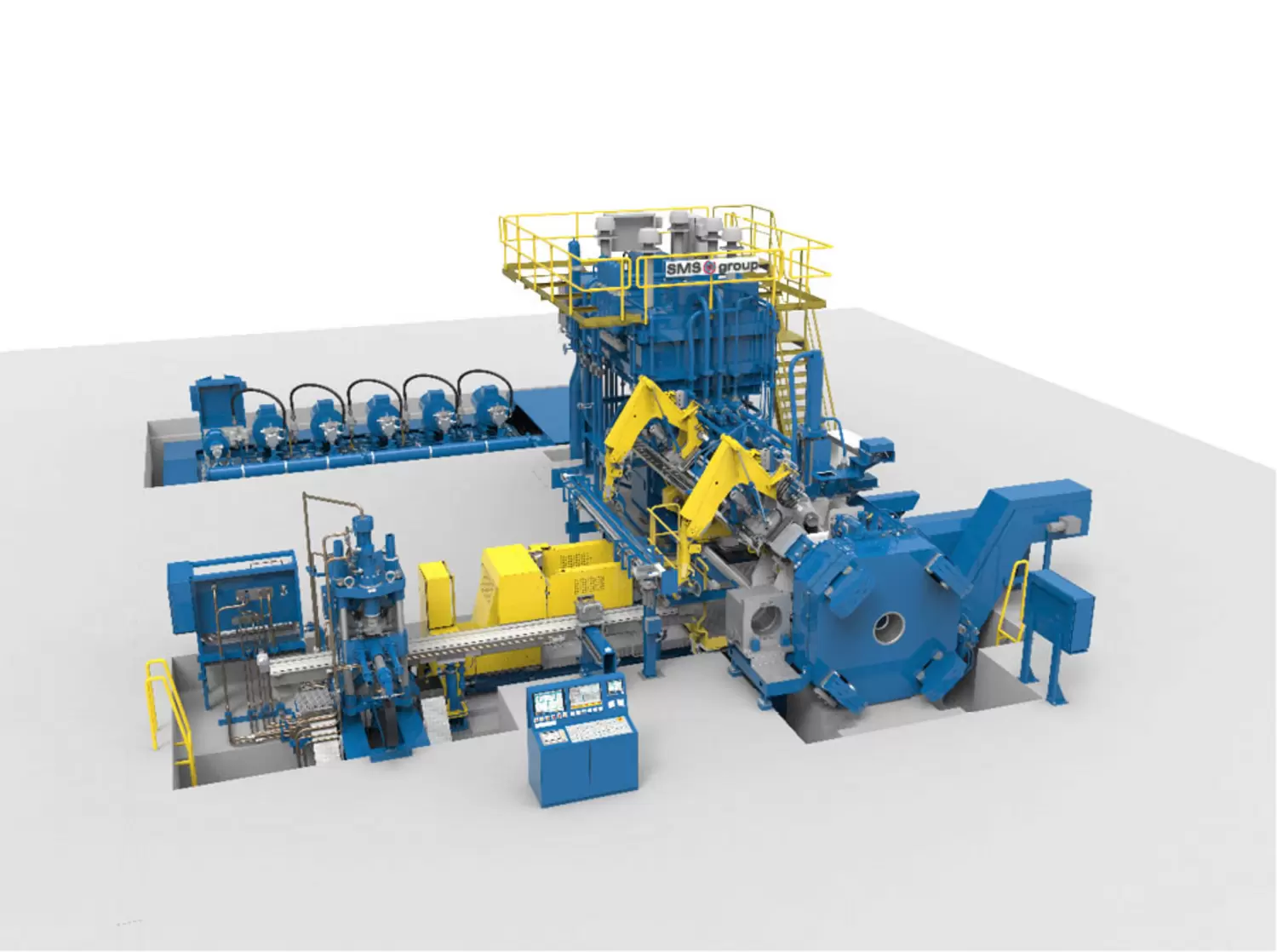

Direct extrusion presses

Wide product mix and small batch sizes

For producers who manufacture a varied aluminum product mix and small batch sizes, direct extrusion is the preferred solution. Short-stroke, front-loader extrusion presses from SMS group are the perfect choice here. They feature FEM-optimized, pre-stressed press frames in the classic Schloemann lamellar tie rod/pressure box design. That makes the frames highly rigid and ensures both excellent profile quality and a long service life. As a supplement to the press itself, our robust linear billet loaders provide precise and optimized motion sequences during loading.

![]()

Direct extrusion presses -

HybrEx® extrusion presses

Innovative extrusion press generation for energy-efficient production

HybrEx® extrusion presses consume up to 55 % less energy, while increasing your productivity by up to 20 % at the same time, depending on the application. This qualifies the HybrEx® extrusion press for our Ecoplants label which denotes economically and ecologically convincing solutions from SMS group.

The new extrusion press generation implements a hybrid drive concept. The HybrEx® hybrid drive system is based primarily on electric servomotors, which are more efficient, faster, and more precise than the mainly hydraulic machines. The hydraulic drive in the HybrEx® extrusion presses is used exclusively to generate high forces for the extrusion process, for discard shearing, and for die cassette shifting.

![]()

HybrEx® extrusion press -

Indirect extrusion press

Ideal for extruding aluminum hard alloys

Indirect presses are ideal for extruding aluminum hard alloys such as AA2xxx and AA7xxx. That's because the lack of friction between the billet and container ensures a reduced extrusion force and optimized material flow. These factors are essential for producing sections made from high-strength alloys. You can also choose from our range of extrusion presses that combine direct and indirect extrusion methods. These give you the flexibility to adjust your production to meet current market demands.

![]()

Indirect extrusion press -

Tube extrusion press

Innovative extrusion press generation for energy-efficient production

Our tube extrusion presses are front-loading or back-loading presses with an internal inline piercing device. Combined with the linear guiding system for the container holder and moving crosshead, this piercing device ensures excellent eccentricity tolerances for extruded seamless tubes.

![]()

Tube extrusion press

Use our contact form for questions, inquiries or personal contact.

-

Press feed lines

For your extrusion line, OMAV, a subsidiary of SMS group, offers sophisticated press feed equipment:

- LOG storage

- LOG furnaces

- Cold or Hot LOG cutting lines

- Billet transfers

- Scalpers for billets

![]()

Press feed line -

Induction heating

Induction heating is 100-percent CO2-neutral during the production process. In addition to the vast range of possible, customized solutions, the plant concepts of SMS group offer maximum flexibility in production as the required energy is applied precisely where it is needed just by “pushing a button”.

![]()

Induction heating -

Profile handling

The handling equipment offered by OMAV is highly versatile and depends on the process types. The handling equipment includes:

- Quench systems

- Puller systems

- Cooling table belts

- Stretchers

- Profile cutting lines

![]()

Profile handling -

Aging and annealing ovens

With aging and annealing ovens from OMAV your products reach the best mechanical properties. We provide the most efficient solutions for:

- Aging ovens

- Annealing ovens

- Electric ovens

![]()

Aging oven -

Basket handling

For basket handling OMAV supplies fully automated solutions:

- Roller conveyors

- Chain conveyors

- Shuttle conveyors

- Basket stackers/destackers

- Basket cranes

![]()

Basket handling -

Basket warehouse and dies warehouse

The product range of OMAV is completed by basket warehouse and dies warehouse:

- Automatic bridge cranes

- Dies warehouse

- Software logistic manager (DMS)

![]()

Basket warehouse

-

ecoDraulic

Intelligent power control

With the ecoDraulic system, more than ten percent of energy is saved in the area of the main drives. The ecoDraulic system is an integrated intelligent automatic start-stop system for the drives of hydraulic pumps. The drives of the hydraulic pumps that are not used in the pressing process are switched off and only switched on again when the power is needed.

![]()

ecoDraulic

Services for your plant

Sorry, there are no results for the search term.

SMS group email service

Our promise to you: this is not just another newsletter!