Running a hot strip production facility these days places high demands on the future viability of the equipment. Our hot rolling mills are capable of producing flat steel from thin gauges of 1.2 mm to high-strength steels up to 25.4 mm thick, including stainless steel. Apart from the outstanding technological quality of our plants, which we continuously develop, we are also committed to our long-term technology partnership, so that your production always meets all the requirements of your customers.

-

High-capacity hot strip mill

Flagship in hot rolling for capacities of up to 6.0 million tons per year

Main dataIt’s due to their high output capacity and flexibility that hot strip mills (HSM) are key to efficient production of flat products. Once you have decided to put your trust in SMS group’s technological expertise, the hot strip mill will serve you for many decades. Our high-capacity hot strip mill is most capable in terms of output, sustainability, and outstanding hot strip quality. This applies both to the production line as a whole and to each equipment and core component.

![]()

Hot strip mill layout -

Compact hot strip mill

Hot strip production with small footprint but numerous options

Main dataA compact hot strip mill comes with reasonable invest and provides the opportunity to grow flexibly with market needs in terms of capacity, product dimensions, and product mix or quality requirements. From an annual production of around 1.5 million tons of hot strip, a compact hot strip mill can be operated profitably and systematically expanded stepwise to a capacity of around 4 million tons.

![]()

-

Steckel mill

Hot rolling specialist for sophisticated grades

Main dataOur Steckel mills are characterized by their outstanding flexibility and low conversion costs. That makes them the appropriate solution for smaller capacities of up to 1.8 million tons per year in hot strip production. When it comes to rolling of stainless steel grades and special alloys, they can hardly be exceeded in terms of efficiency.

The single-stand Steckel mill is mostly used to produce small batches in an annual capacity range from 100,000 to 600,000 tons. If a roughing stand is included in the line, the capacity can be increased up to 1 million tons per year.Our Steckel Plate Mill combines Steckel technology and plate rolling to produce plates and hot strip in a single line.

![]()

-

Twin-stand Steckel mill

Steckel mill technology combined with tandem rolling

Main dataA Steckel mill can also come with two rolling stands as a twin-stand Steckel mill. Similar to the conventional single-stand Steckel mill the twin-stand Steckel mill operates also in reversing mode, but with fewer reversing passes. It provides you with a capacity of 1.0 to 1.2 million tons per year. If a roughing stand is integrated in the production line, capacity can be increased to 1.8 million tons per year.

Apart from the design of the rolling mill, the line concept and the equipment is basically the same as in single-stand Steckel mills.

![]()

Use our contact form for questions, inquiries or personal contact.

-

X-Roll® Guide Concept

Highest stability of the hot rolling process

The stability of the hot strip mill remains a main topic, especially when it comes to the processing of thin and hard materials. Strip steering mainly at the end of rolling and tail out is one reason for unscheduled downtimes. The new X-Roll® guide systems are capable of improving mill stability and product quality.

-

X-Roll® Cooling Concept

Solutions for optimal temperature settings and best material properties

Strip cooling is an important process in hot strip mills. To establish flexible cooling strategies and to achieve a wide range of cooling rates, we offer different cooling system modules. We combine these modules to provide you with a money-saving solution geared to any product range.

![]()

Modern laminar cooling system by SMS group -

Superior hot strip quality

Improved product tolerances due to excellent strip profile and flatness

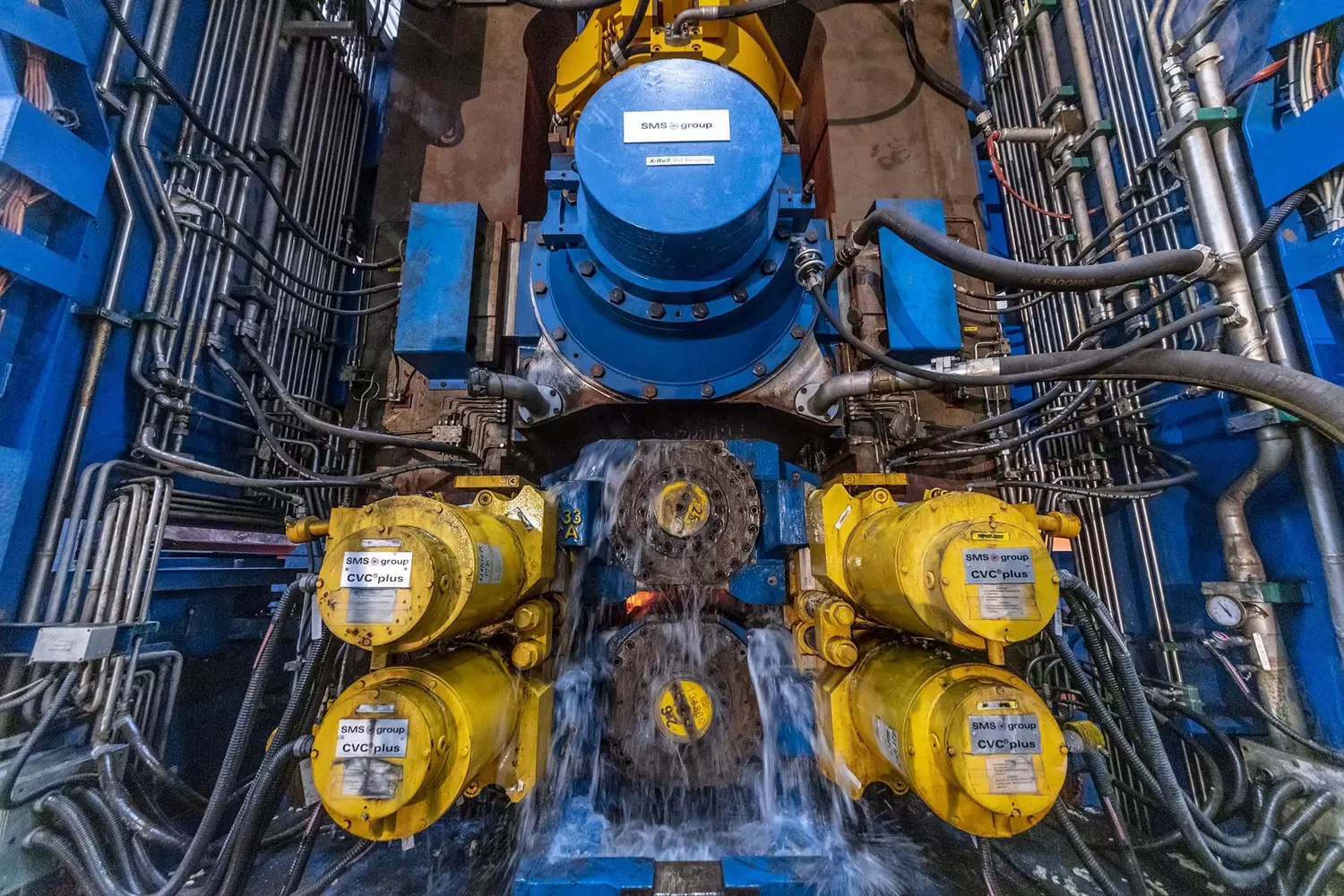

To keep hot strip quality parameters always on a high level, we offer you a number of key technologies, especially with regard to strip profile and flatness. Of course, the best results are to be expected when implementing the entire package. But the modular structure of our technologies also allows individual application with reasonable results.

-

Improvement of hot strip surface

Advantageous not only for rolling of silicon steels

In connection with the global climate protection objectives, and their effects on many areas of life, the demand for electric strip is continuously rising. This poses special challenges to the process guidance and control during hot strip production. Our modular technology package ensures that the dreaded edge cracks do not occur at all and prevents the valuable rolling stock being depreciated as a result.

Silicon steels are particularly temperature-sensitive due to their chemical composition. At the same time, the material is very valuable, so that reductions in the strip quality or even re-melting of the material are economically very detrimental. The technical solution offered by SMS group aims at the consistent control of temperature throughout the entire hot rolling process. In particular, at the strip edges, as this prevents temperature losses and thus the risk of cracks. In addition, a highly effective descaling system is used.

![]()

Silicon steel is required for the erection of wind turbines. Benefits

- X-Roll® Interstand equipment

- Efficient fluid system for descaling, provided with the latest piston pump technology with frequency controls and the latest valve technology with optimized flow characteristics and low wear. In addition, a new generation of hot strip mill descalers with pressures up to 380 bar will be soon introduced to the market.

- New generation of top and bottom pinch roll polishers

- X-Roll® Guide Coiler, implemented in the downcoiler area, providing an accurate coiling process and result

- Edge heater in front of the finishing mill