Annealing lines and galvanizing lines from SMS group are characterized, in particular, by the excellent quality of the end product, high efficiency and economy, as well as enormous capacities. In recent years, various improvements and new technical solutions have been developed, particularly regarding line concepts, furnace technology, galvanizing technology, and post-treatment.

Multiphase steels, which are high strength and very ductile, are increasingly being used for car components. These high-strength yet easily deformable steels must meet the highest quality requirements for use in automobiles.

In the lines, account is taken of the stringent demands on surface quality. This commences with cleaning, which is followed by surface-friendly annealing, and high-grade coating technologies for the application of a zinc layer, passivation, or preserving oils. Advanced annealing and cooling strategies are implemented, together with a skin-pass mill stand for targeted post-treatment, in order to achieve outstanding material strengths.

-

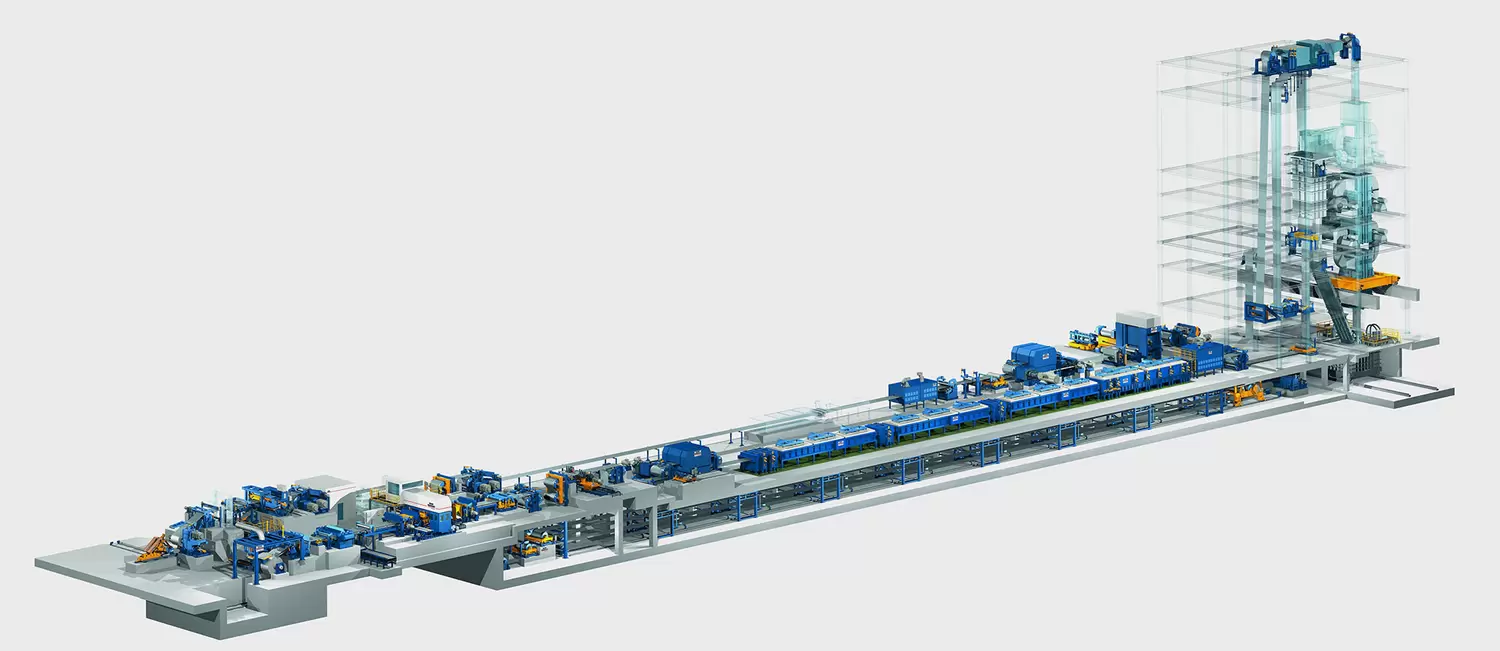

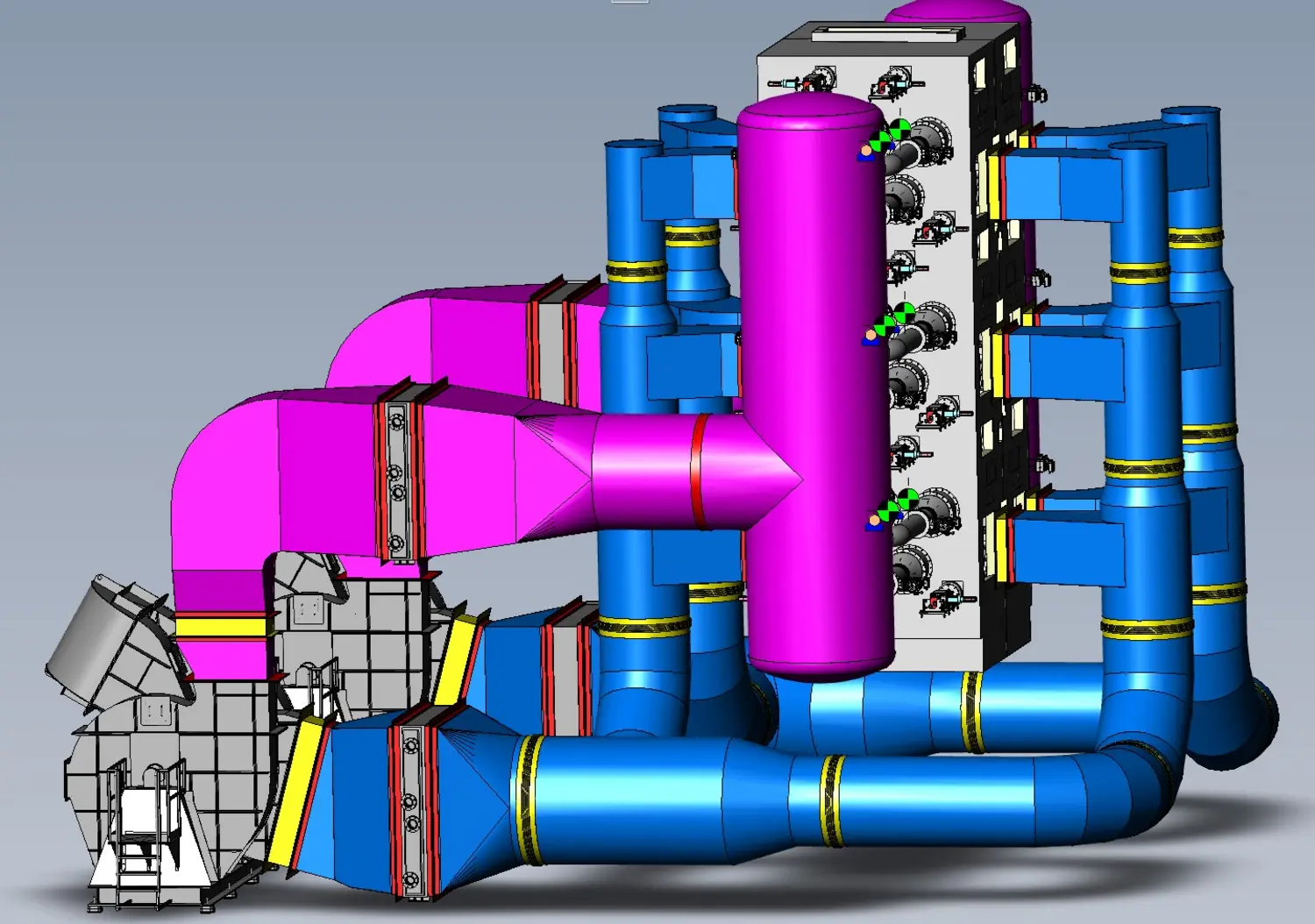

Hot strip galvanizing line

Zinc-coated steel strips with long-life corrosion protection

Main dataThe galvanizing of hot strip enables the production of zinc-coated steel strips with long-life corrosion protection and an attractive look at low production and investment costs. There is a growing market and increased demand for variuos applications for galvanized hot strip, for example in the construction, furniture, or automotive industries.

Economically speaking, the use of galvanized hot strip is particularly attractive for applications where a galvanized cold strip would normally be used. Because a number of cost-intensive process steps are skipped from the production of galvanized hot strip compared to the production of galvanized cold strip, enormous cost advantages arise here, which ultimately increase the margins of the steel producers.

-

Automotive lines

Cold strip annealing and galvanizing line

Main dataThe annealing lines and the continuous galvanizing lines are the most important cold strip processing lines for the production of automotive grades, whereby both high-level exposed surface quality and high-strength materials are required.

![]()

-

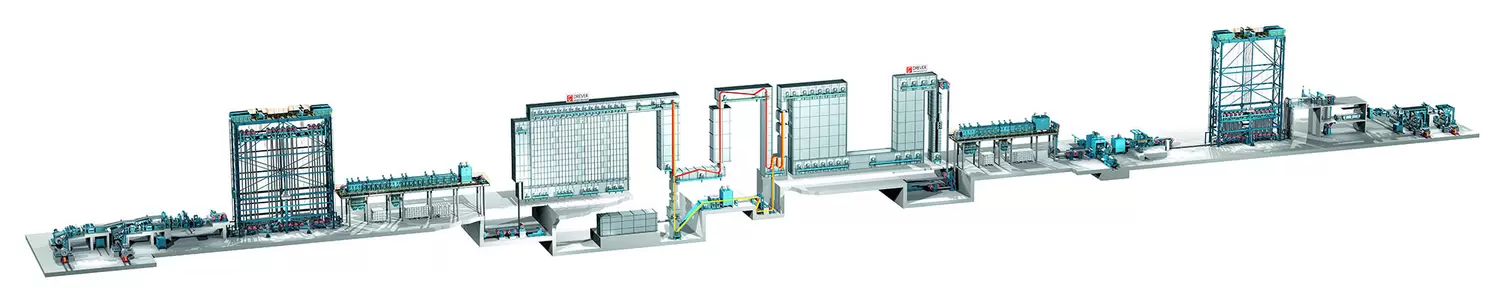

Horizontal galvanizing lines

Cold strip annealing and galvanizing line

In addition to the lines, which are designed mainly for automotive quality, SMS also offers some simpler line concepts, which are intended mainly for the production of materials for the construction, household appliances, or furniture industries. These lines can also be used in part to produce materials for automotive applications.

![]()

-

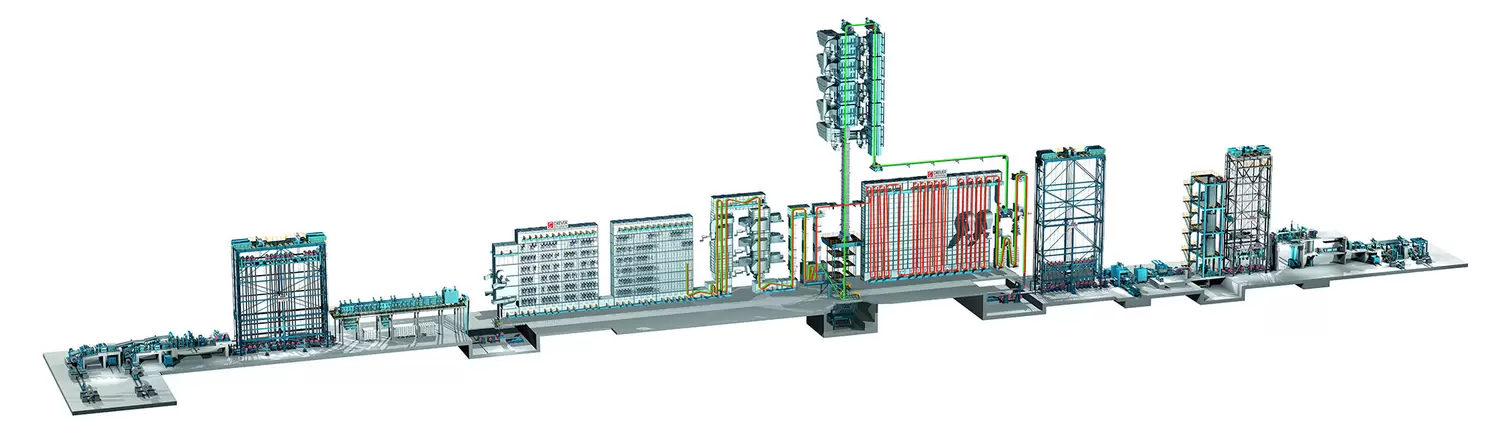

Universal annealing line with rapid cooling and water-spray cooling

Multipurpose line for flexibility and cost-effectiveness

Automotive lines from SMS group stand out due to their extreme flexibility thanks to the highly developed, tried-and-tested technologies and components that are applied. Apart from an ultrafast cooling zone with cooling rates of up to 150 kelvin per second and millimeter of strip thickness, this type of line comes optionally with a water-spray cooling system that achieves cooling rates in excess of 1,000 kelvin per second and millimeter. This makes it suitable not only for the high-strength grades that require rapid cooling, but also for martensitic and dual-phase steels with tensile strengths of 1,550 megapascals and more.

![]()

-

Universal annealing and continuous galvanizing line

Annealed and galvanized cold strip in extremely high quality

Here is a special type of line in which the cold strip first goes through recrystallization annealing, then moves on to either a zinc bath or an overaging zone. You benefit from a flexible line that produces two different product groups (annealed and galvanized) in extremely high quality.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

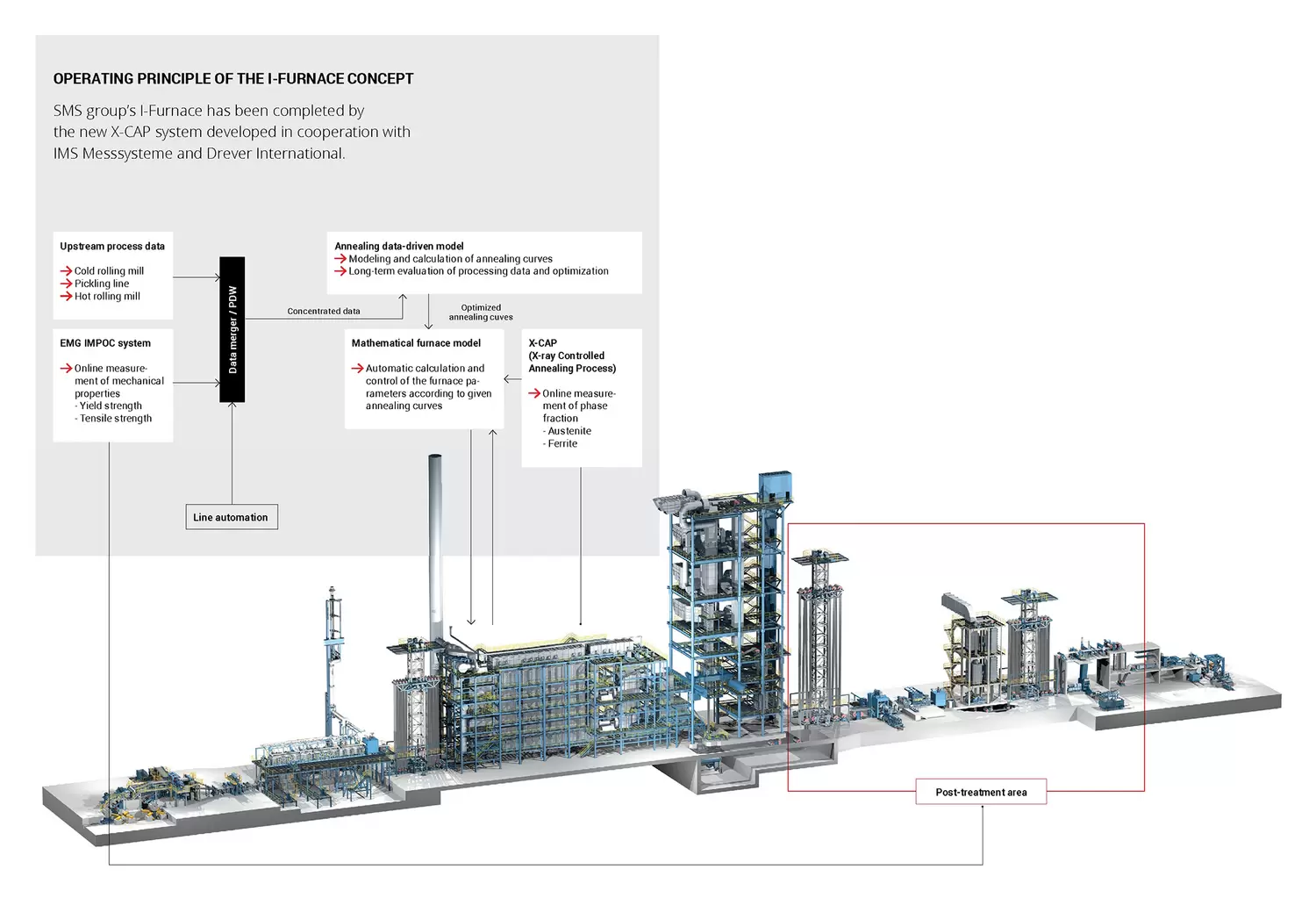

Intelligent furnace with X-CAP® technology

Prediction of material properties

The production of modern AHSS grades places high demands on the thermal process in annealing and continuous galvanizing lines. In particular, the automotive industry requires homogeneous properties of the steel strips from coil to coil and along the coil length. In order to achieve this, information on the microstructure of the strip is necessary to control the process and compensate possible deviations caused in the upstream processes.

Therefore, SMS group developed the I-Furnace (Intelligent Furnace) including a smart annealing process and a production optimization model. Here, the combination of various tools leads to an optimized heat treatment and production process. Furnace control, online strength measurement, and a model to predict the material properties after annealing are combined and linked. However, the control of the process with a measurement system in the exit section of the line, far behind the process, has a long reaction time and at that position final mechanical properties are already adjusted. Thus, a further measurement system including a control model has been developed in addition to the already existing tools to complete the I-Furnace.

SMS group, Drever International, and IMS Messsysteme jointly developed X-CAP® (X-ray Controlled Annealing Process), permitting the steel structure to be measured within the annealing process and hence the mechanical properties to be controlled in a closed loop first time, direct in the relevant process section.

![]()

Operating principle of I-Furnace -

UFCplus

Rapid cooling with gas

To reach the highest cooling rates with gas cooling Drever developed the advanced gas jet cooling system UFCplus. With this cooling system, higher cooling rates of up to 150 kelvin per second per millimeter are obtained by adding pure hydrogen to the cooling chamber without increasing the total hydrogen consumption of the line. A patented hydrogen migration technology limits the diffusion of hydrogen into the adjacent chambers. Thus, a hydrogen content in the cooling chamber of up to 50 % can be reached while keeping the hydrogen content in the other sections still under 5 %.

![]()

UFCplus -

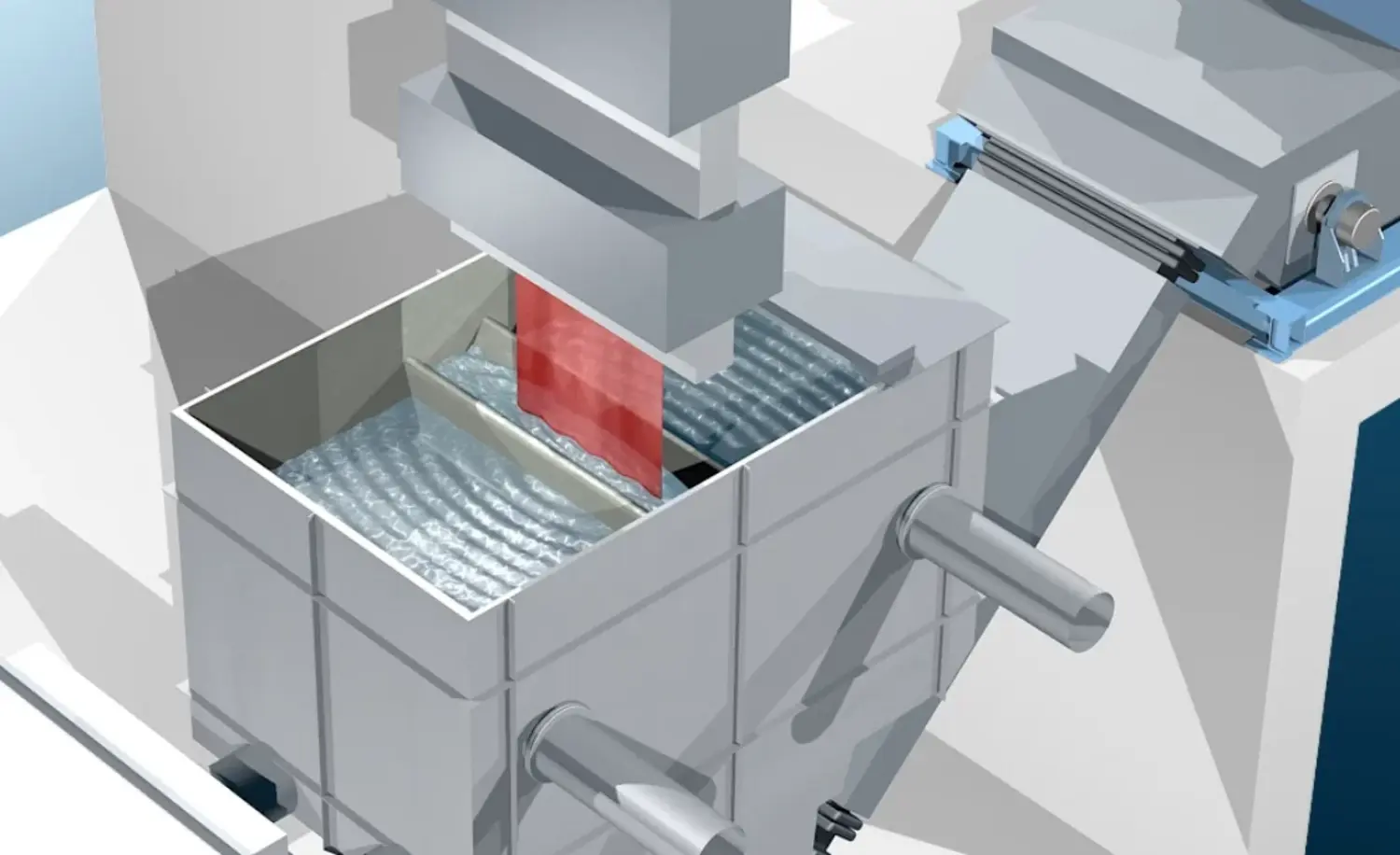

Intensive cooling with water

Water spray rapid cooling

The water spray rapid cooling system involves immersing the strip in demineralized water while special nozzles spray it from both sides at high pressure. Here, the cooling rate is more than 1,000 kelvin per second and millimeter of strip thickness, enough for manufacturing tough dual and complex-phase grades and martensitic grades with tensile strengths of 1,500 megapascals and more.

![]()

Water spray rapid cooling -

PrOBOX®-technology for pre-oxidation

Efficient heat treatment for all qualities

Wettability problems in the conventional continuous galvanizing process due to high alloyed materials can be prevented by a specific oxidation and reduction process, for which SMS group offers the PrOBOX ®-technology. PrOBOX ®-technology has become widely accepted as the best process for continuous galvanizing of high-strength steel grades with high silicon and manganese contents. For this purpose, on the strip surface the targeted reference oxide layer is adjusted during the annealing process at temperatures between 600 and 700 °C.

![]()

PrOBOX®-technology -

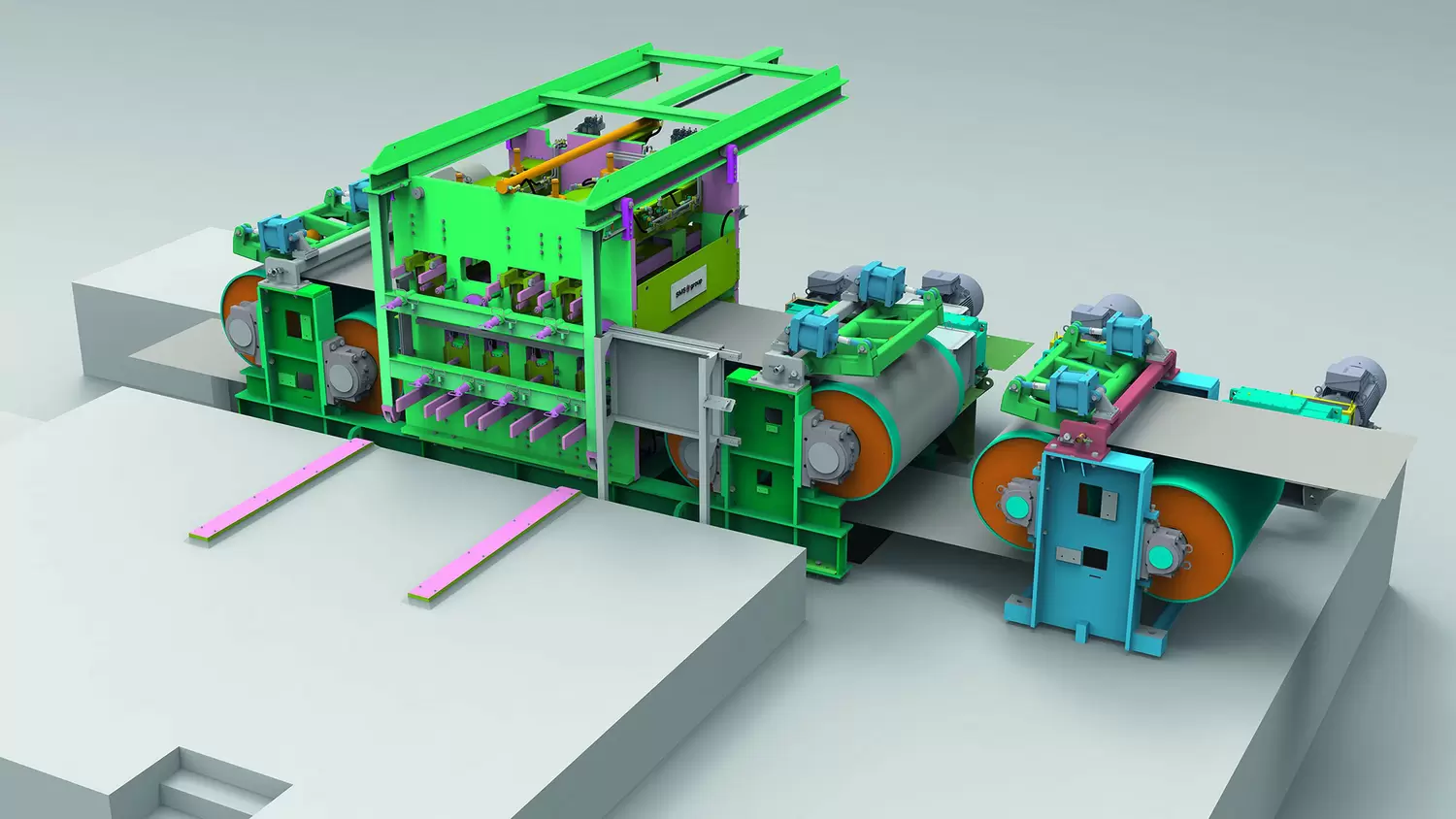

Tension leveler

For high-strength grades

Tension levelers minimize irregularities such as waviness, cambers, or length- and crossbows using a combined tensioning and leveling action to create a flat final product. Market demands for higher material strengths lead to exacting changes in machine technology. One aspect is higher forces in stretching and bending. SMS group has developed tension levelers for cold as well as hot strip lines that are capable of leveling steel strip with yield points much higher than 1,000 megapascals. The machines are also suitable for installation in existing plants to make these facilities meet future material requirements.

![]()

Tension leveler -

Integrated solution air knife systems

Ultimate surface quality

In principle, electromagnetic strip stabilization systems feature electromagnets arranged on both sides of the strip at the same height above the air knives. A position measuring system is installed below on each magnet position, which continuously measures the position to the strip in a non-contact manner. The strip position determined by this sensor is compared to the reference position. Due to this deflection, the electrical current is prescribed to the stabilization coils on the top or bottom side and results in the magnetic attraction of the steel strip. In this way, the crossbow of the steel strip is minimized and vibrations are reduced. Consequently, the distance of air knife lip to strip surface can be reduced. To satisfy today’s requirements on surface quality, an integrated solution has been developed, which brings air knife and strip stabilization closer together.

![]()

Strip with excellent surface quality -

X-Roll® laser welder

Fast, safe, and successful welding of challenging steel grades

The X-Roll® laser welder is designed to join hard-to-weld strip material. The laser welder comes with a patented, inductive heat treatment system including automatic welding parameter calculation system, a quality assurance system, and an exchangeable laser source. The laser welder has been installed in new plants as well as in modernization projects.

![]()

Services for this plant

Sorry, there are no results for the search term.