Comprehensive engineering, project development, and execution in bright bar machines and equipment

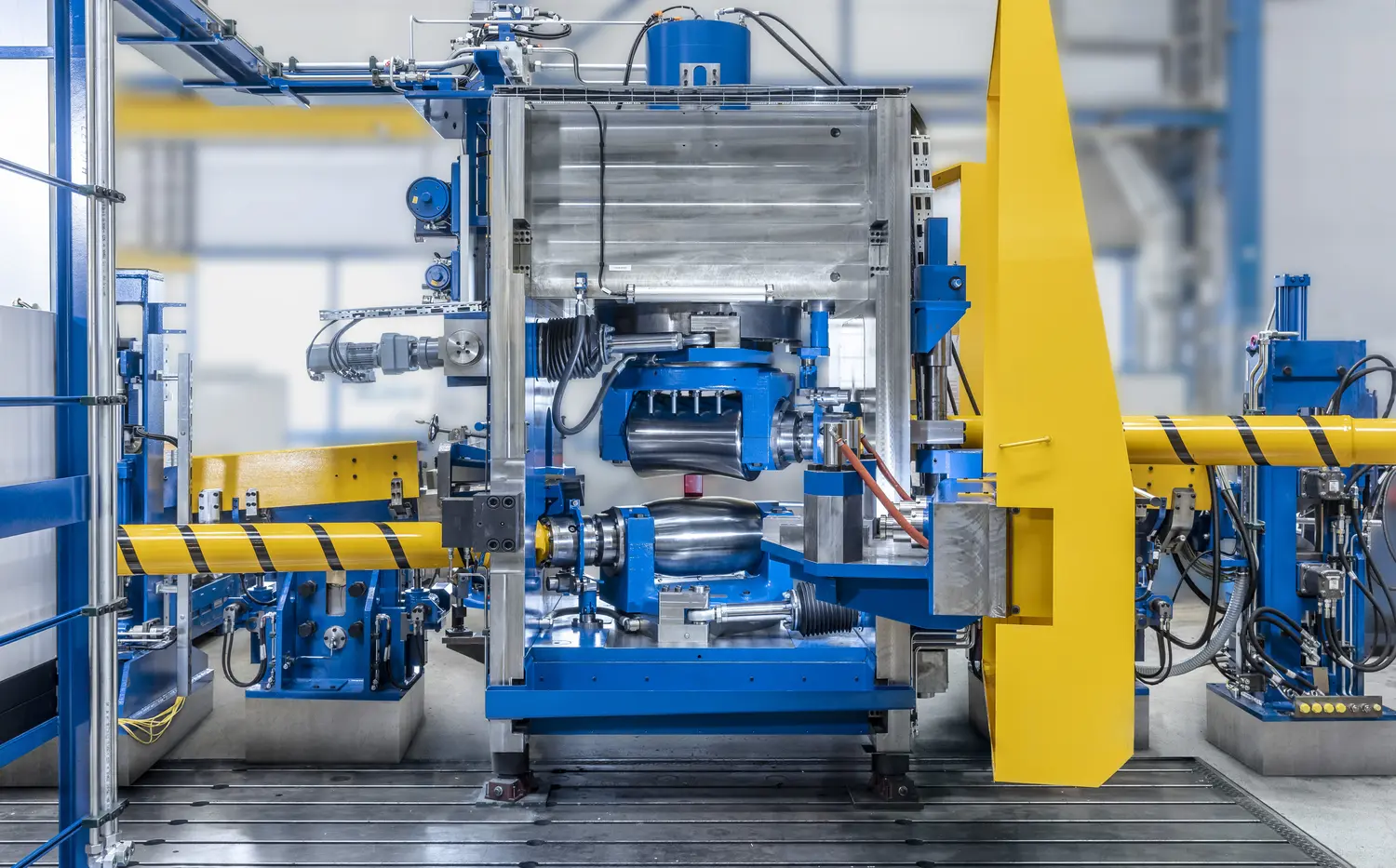

With over 80 years of expertise, SMS group offers advanced machinery solutions for processing bright bars, essential in automotive and medical industries due to their smooth surfaces and dimensional accuracy. We provide high-performance drawing, peeling, straightening, and grinding lines tailored for optimal production efficiency. Our PMH series peelers handle large diameter bars (60–630 mm) with high efficiency, surface quality, and precise tolerances, optimized for challenging steel grades like superalloys.

Our engineering capabilities ensure innovative design and customization to meet specific client needs. Our project development expertise focuses on comprehensive planning and resource management, while project execution guarantees timely delivery and operational excellence. Additionally, we offer comprehensive services for SCHUMAG, KIESERLING, and SMS plants, ensuring high plant availability with modernization, spare parts, and repair services.

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

Global presence

SMS group maintains a global presence in bright bar services, offering comprehensive support to customers worldwide. With decades of expertise, we provide spare parts, maintenance, modernization, and repair solutions to ensure high plant availability and optimal performance. Our service network spans key regions, enabling rapid response to planned and unplanned downtimes. Leveraging OEM knowledge and an experienced supplier base, we deliver tailored solutions for SCHUMAG, KIESERLING, and SMS bright bar plants. This global reach ensures consistent quality and reliability across all service operations.

Our long-standing history in bright bar processing

SMS group's acquisition of KIESERLING and SCHUMAG marks a significant milestone, integrating two companies with a rich history in bright bar processing. Both KIESERLING and SCHUMAG have long been recognized for their excellence and innovation in drawing line technology, serving industries with precision and reliability for decades. By bringing these renowned entities under our global footprint, SMS group enhances its ability to offer comprehensive services and solutions, ensuring customers benefit from a wider range of expertise and resources. This strategic integration allows us to deliver unmatched support and service quality, maintaining high plant availability and operational efficiency across the globe.