The competence teams of SMS group all over the world offers a unique competence pool with wide-ranging products and services for our customers in the non-ferrous metals and alloy industry. We have expanded our competencies, from the smelting of the ore or other metal-containing sources right up to a variety of different high quality grade metals. Additionally, we develop tailor-made solutions for the refining of metals and alloys, assuring a high metal product quality.

-

Tilting refining furnaces (TRF and ETRF)

Smelting, refining and casting in one unit

The TRF and ETRF are designed for smelting and refining different scrap qualities and are optimized primarily for copper scrap recycling. They offer the best flexibility in terms of scrap mix and process control. For process optimization these furnaces can be combined with the SMS group BlueControl process control system.

-

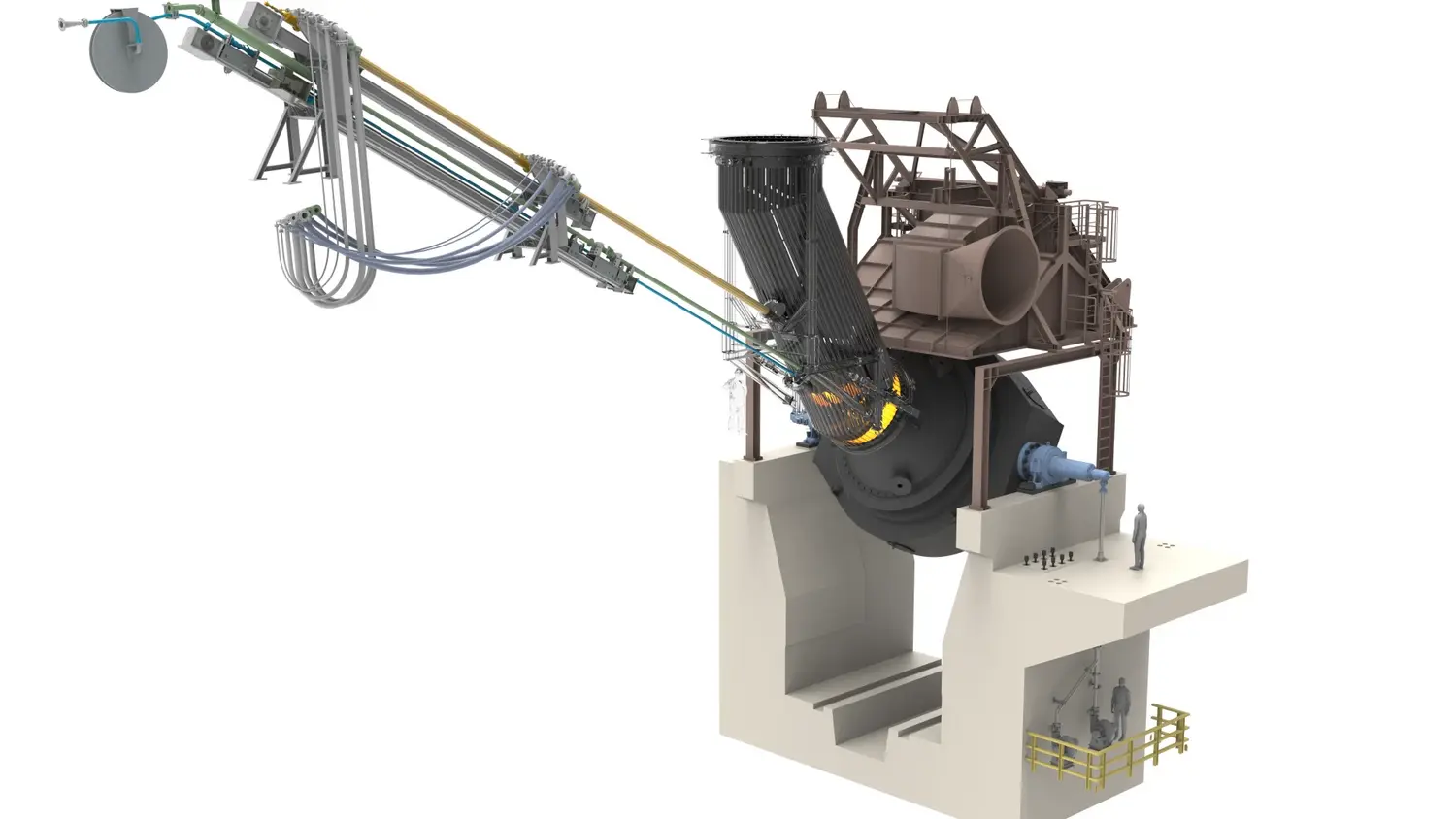

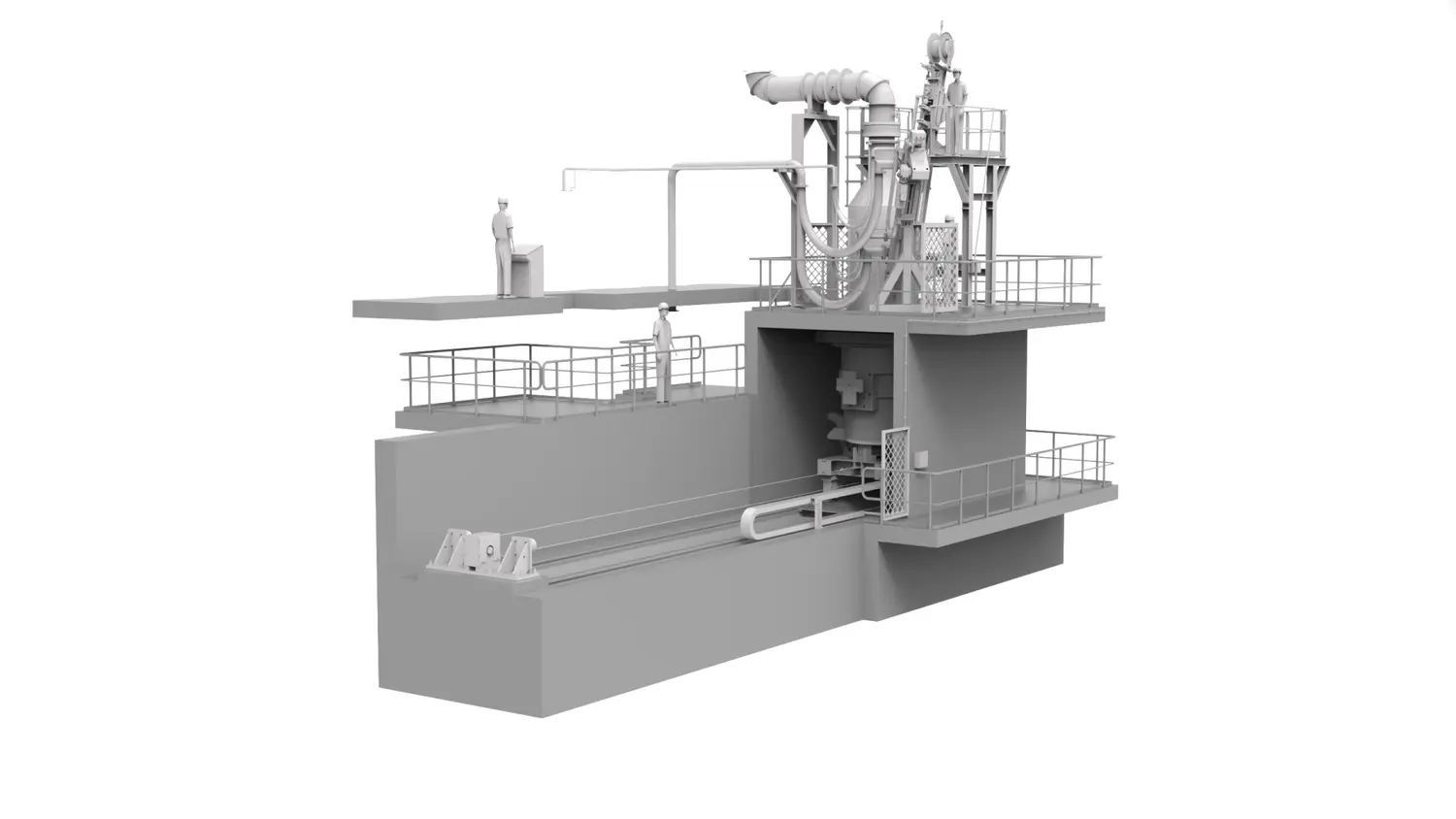

Top blown rotary converter (TBRC)

Smelting, converting and refining various raw materials with high melting and refining efficiency in one flexible unit

The TBRC combines smelting, converting and refining functions into a single, versatile reactor. An optional slag-treatment configuration further enhances metal recovery and waste minimization.

![]()

-

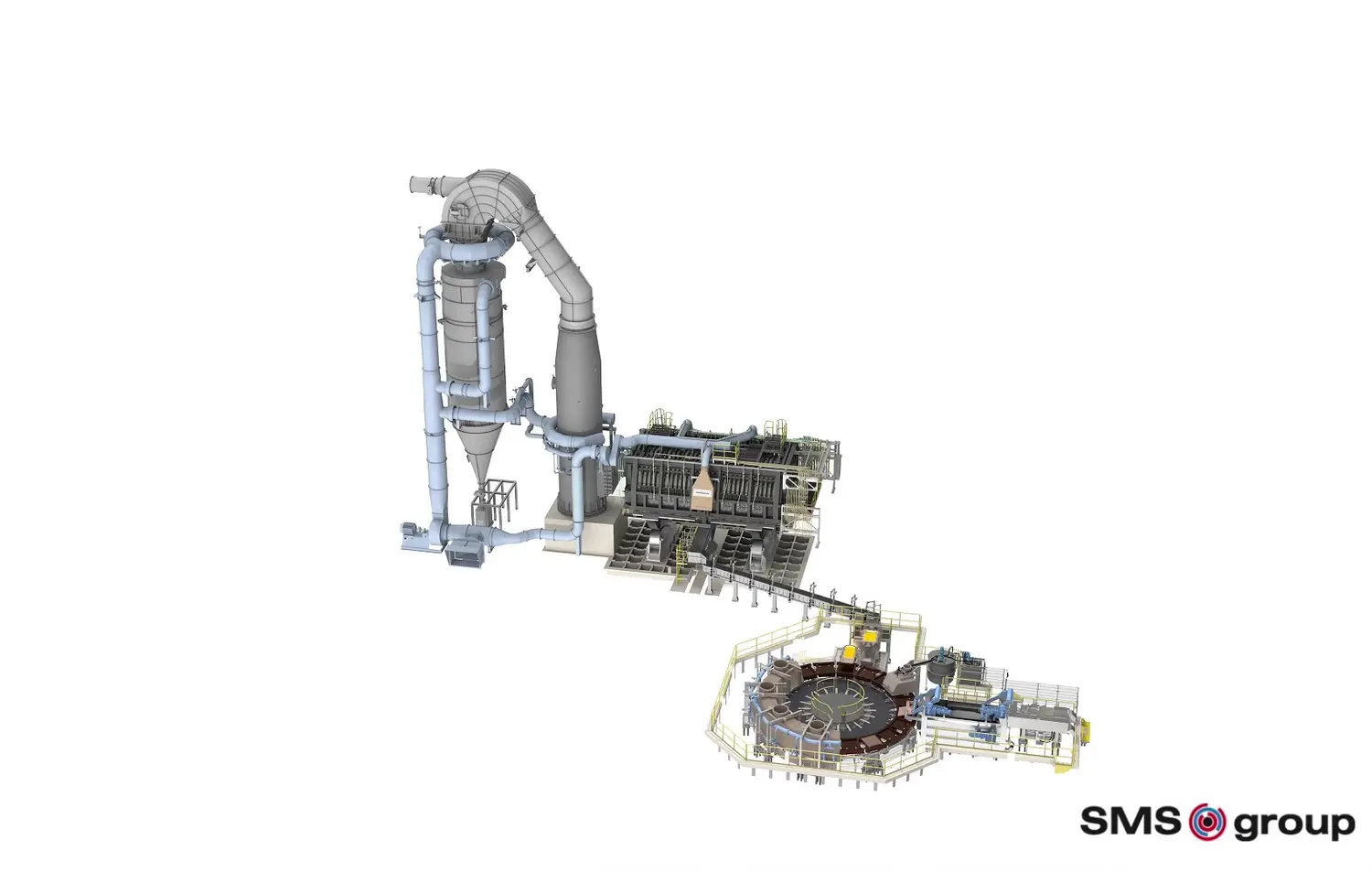

Anode furnaces (ANF)

High copper purity with reduced energy consumption and low emissions

SMS group combines blister- or raw-copper refining with a high-precision casting wheel into a single package—maximizing overall plant efficiency and throughput.

To further enhance fire-refining performance and reduce emissions, our anode furnaces incorporate:

- Novel charging systems for streamlined scrap and matte feed

- Automated de-slagging mechanisms to maintain optimal melt purity and ensure safe operation

- Optimized furnace geometry and refractory lining for improved thermal management

![]()

-

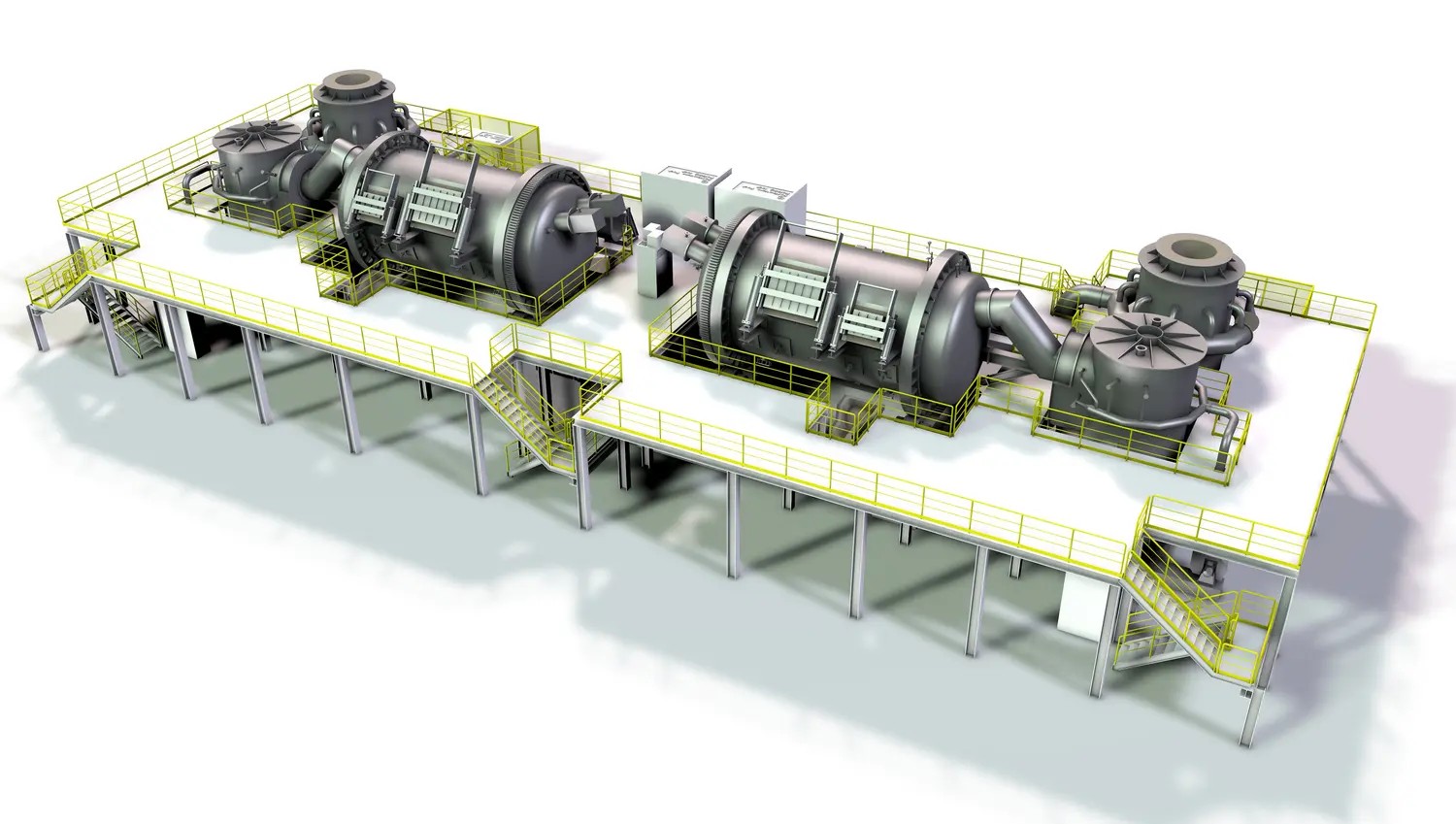

Holding furnaces

Holding and settling furnaces for liquid metal buffering

Holding furnaces are used for a combination of continuous and batch type processes or, more generally, as a buffer for liquid metal. The molten metal is transferred via launders or via ladles into the furnace. The furnace can also be used as a settling furnace to separate the metal or matte and slag by using two different tap holes. Feed ports for additives and purging systems can be installed to enhance the process further.

![]()

-

Ladle furnaces

Ladle treatment furnace for advanced metal refining

SMS group's ladle treatment furnace offers unparalleled efficiency and adaptability in metal processing. Our advanced technology facilitates copper refining through effective desulfurizing and reduction processes. Additionally, the furnace excels in converting copper matte and recycling lead-tin alloys from slags, ensuring optimal resource utilization and sustainability. Embrace the future of metal processing with SMS group's innovative solutions.

![]()

-

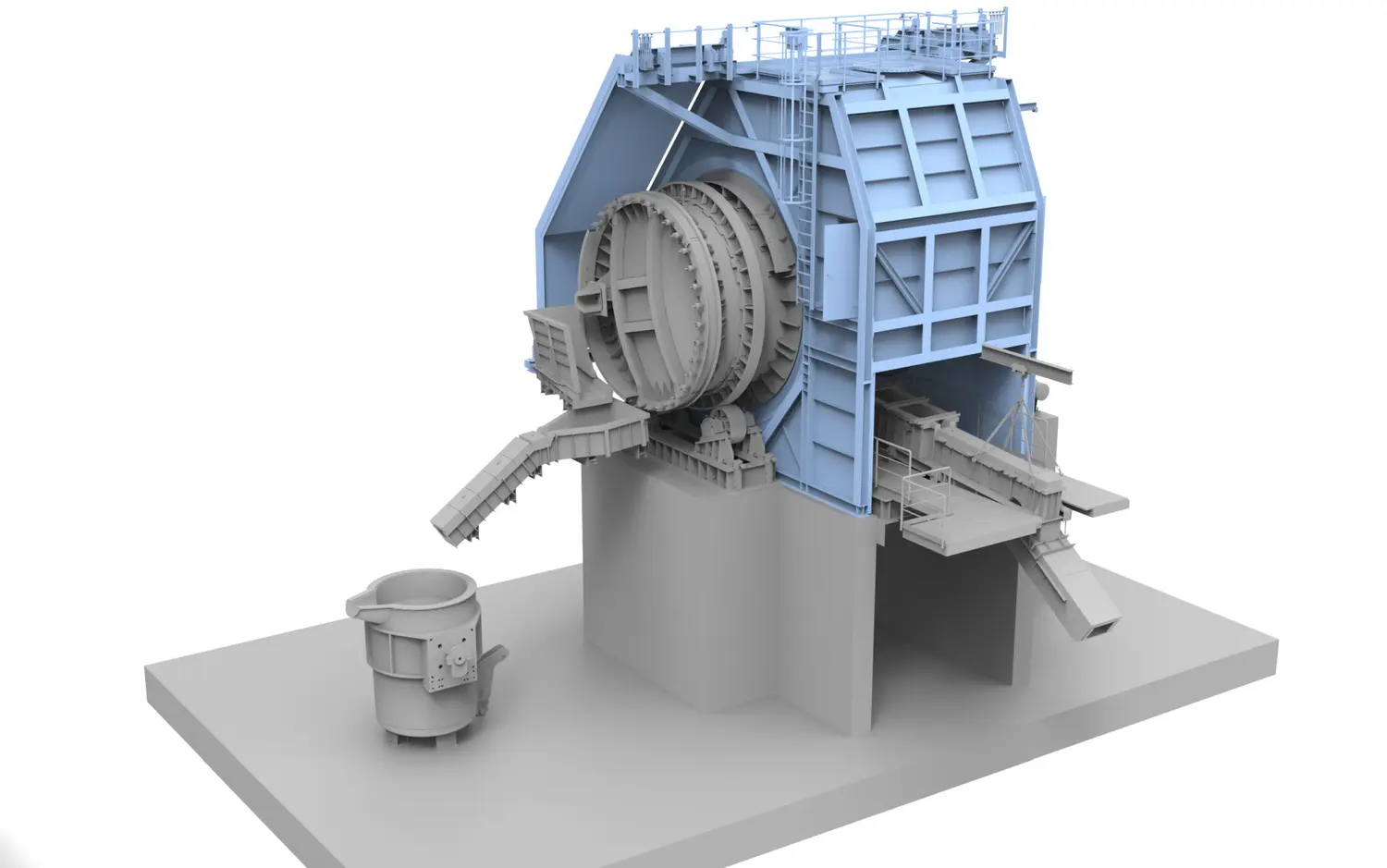

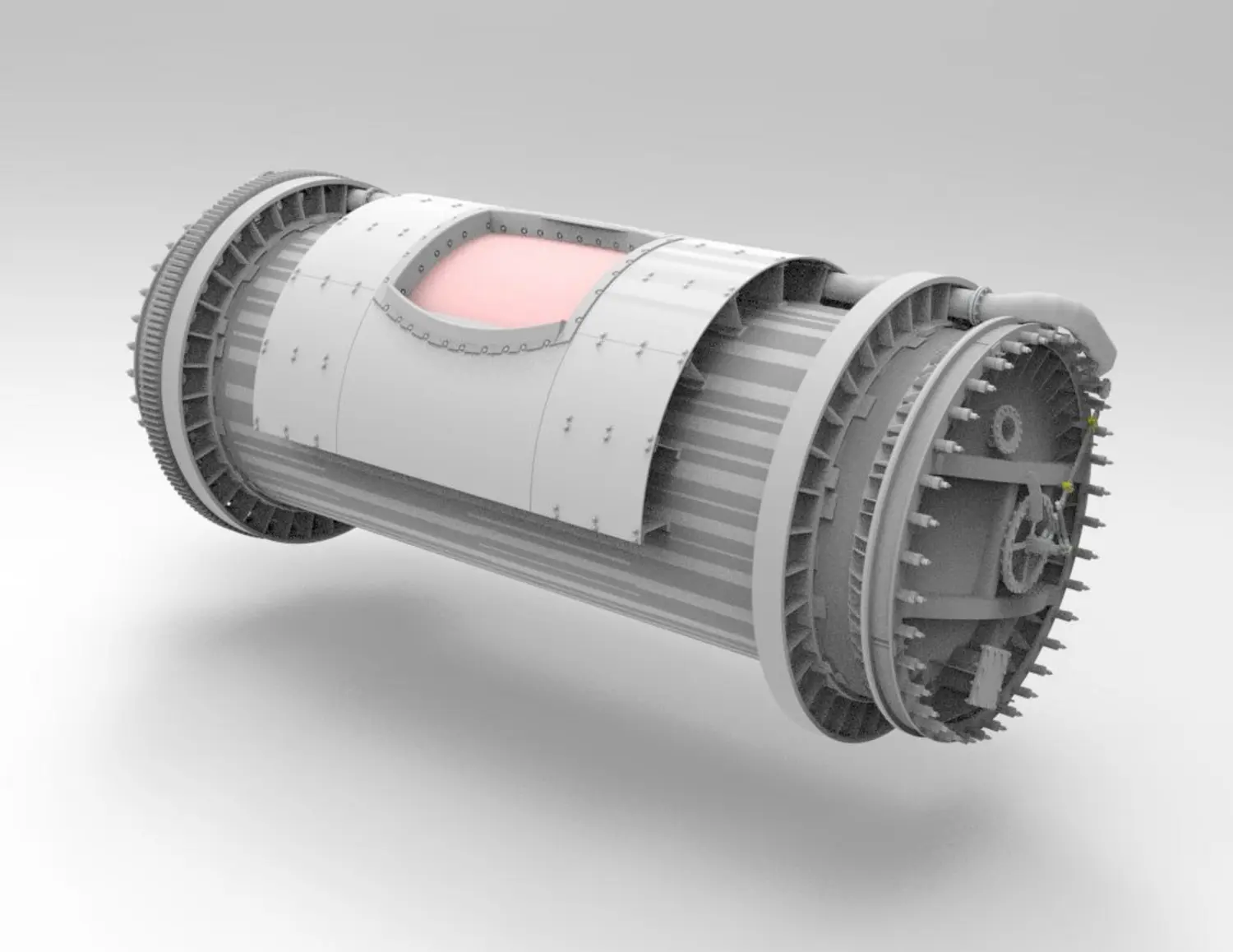

Peirce-Smith converter

Converters for blister and matte production

The Peirce-Smith converter from SMS group is the next logical step in converting – a new solution that implements numerous improvements. This reactor type is still the most widely applied process for blister or black copper production. It is also commonly used in nickel and PGM production lines. Conversion takes place during the slag-blowing stage as well as in separate final converting phases.

Integration with SMS group’s BlueControl system for:

- Real-time O₂, temperature and pressure monitoring

- Adaptive tuyere flow balancing and blow-profile optimization

- Automated sequence management for converter tilting and tapping

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

Services for this plant

Sorry, there are no results for the search term.