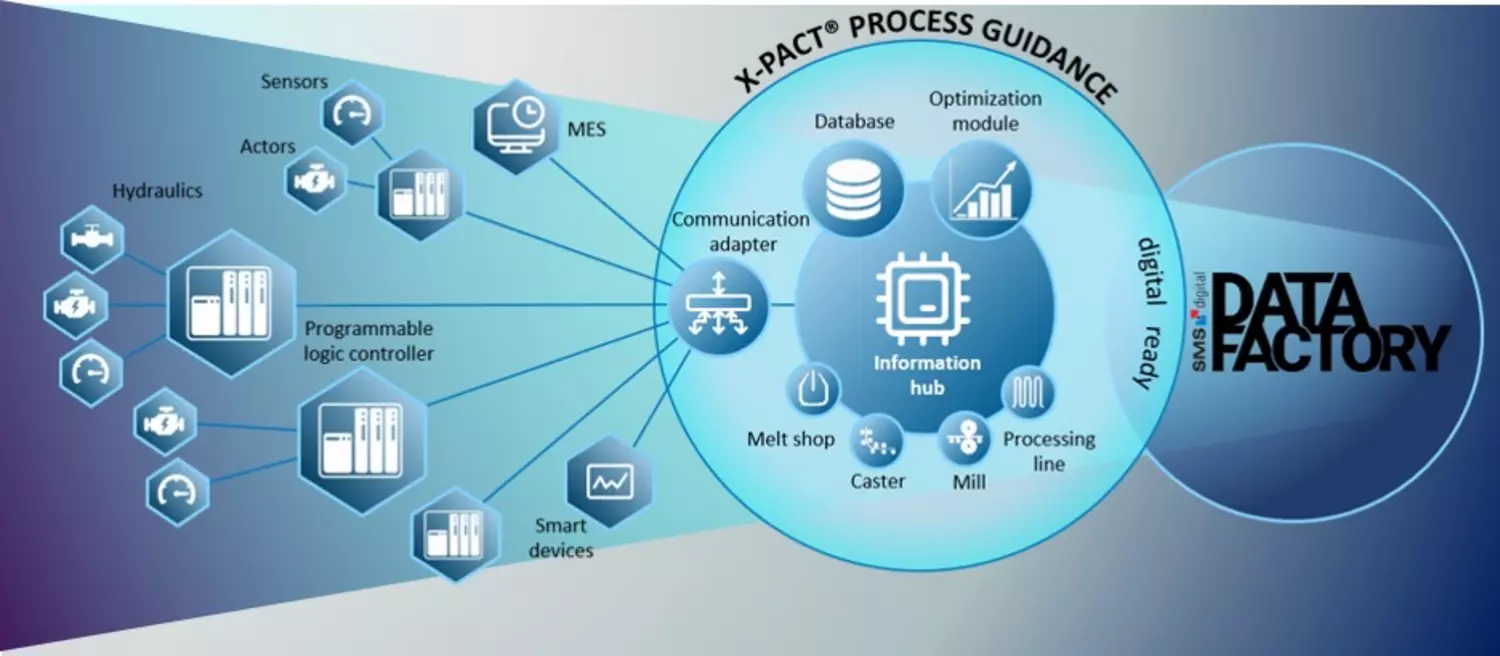

Basic connectivity in all directions

This automation technology creates the necessary transparency for your plant and links knowledge and data intelligently and systematically. Seamless merging of automation levels and a component-oriented system allow extendibility by adding further modules and applications. Process-oriented operational guidance from SMS group ensures that the entire digital environment has the same look and feel across all products.

Benefits

- No break in operation

- High flexible production with ever smaller batch sizes and increasingly wider production mixes

- Handling of special situations through operators, no matter how experienced he may be